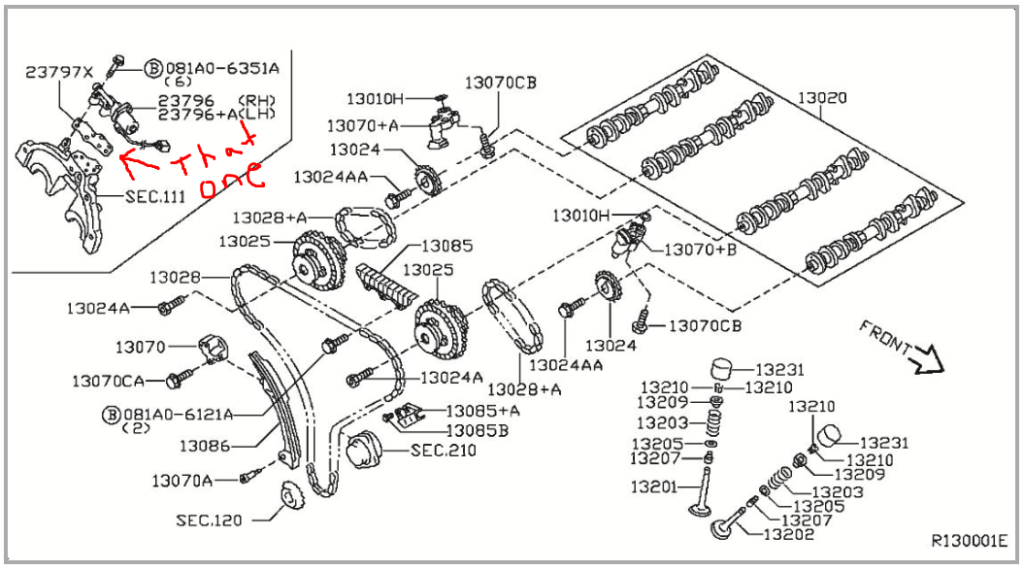

Not too long ago I created a video on replacing the valve covers on the Xterra. While I was making that video I was trying to get a nice clear shot of the mating surface between the cover and the top of the motor. To do that I removed the Intake Valve Timing Control Solenoid Valve. What I didn’t realize at the time was that I was creating a huge problem for myself. When I took off the valve I saw that the gasket was in bad shape.

The problem was not that the gasket was bad. It was that I reused it….

Now hear me out, I know that its a cardinal rule to never reuse a gasket (unless they are reusable) but these are not the types of mating surfaces you can quickly throw some gasket maker onto and call it a day. This gasket was small, intricate, and could only be obtained by custom order. So in the moment I had my engine torn apart, cameras and lights all set up, and a video to finish. I decided to cross my fingers and put it back the way it was.

Fast forward a few months, I am driving down the road and I can smell burning oil. I knew almost immediately that my poor decision had caught up with me. I get home, park the X, and see that its smoking!! I quickly open the hood to make sure that its not actually on fire.

I was happy to find that it was just some oil smoking after dropping onto the exhaust manifold, however I knew it was time to stop driving the X and get these gaskets ordered and replaced. I found what part I needed by heading over to https://parts.nissanusa.com and searching for valve solenoid. I found what I needed pretty quickly.

I called Nissan and I determined that they were only $1.31 ! I was pleasantly surprised as I was expecting it to be like 20 bucks.. So I bought a few, just in case since they are the same for both sides anyway..

I called Nissan and I determined that they were only $1.31 ! I was pleasantly surprised as I was expecting it to be like 20 bucks.. So I bought a few, just in case since they are the same for both sides anyway..

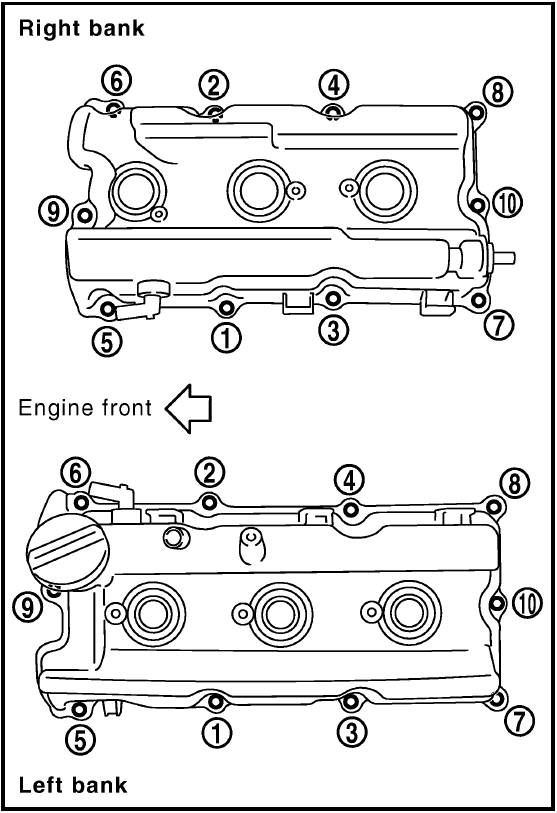

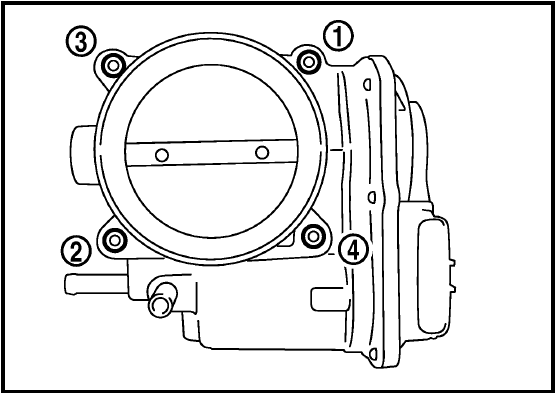

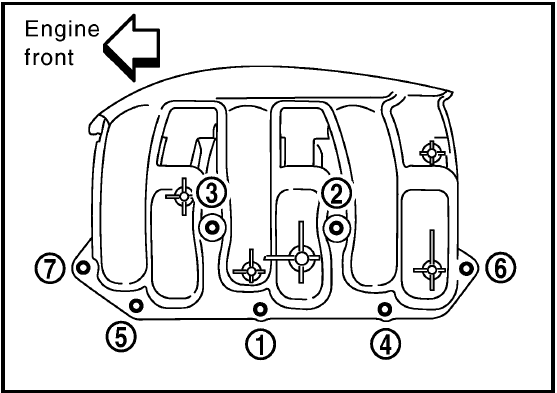

The job itself was not that big of a deal on the driver side bank. The other side required that I remove the intake manifold which if you have ever done it then you know what a huge pain it can be….

In retrospect its easy to say that I should have just left my car in 50 pieces, ordered the part, waited for it to come in, then replace it when finishing up the other job. However, sometimes we gotta do what we gotta do. But hey, look at the bright side, it was another opportunity to make video for all of you out there!

Thanks for reading.

Once that starts happening the oil that is on the heat shield will get crazy hot while driving and create that nasty smell I was smelling. Anyway, I was following the oil up and determined that its coming from the passenger side valve cover.

Once that starts happening the oil that is on the heat shield will get crazy hot while driving and create that nasty smell I was smelling. Anyway, I was following the oil up and determined that its coming from the passenger side valve cover.